Knowing how long does cement take to dry is crucial before you can walk on that new driveway, finish your basement floor, or complete any concrete project. The answer isn’t as simple as “24 hours”—there’s a lot more happening beneath the surface, and getting the timing wrong can ruin weeks of work.

Table of Contents

Initial Set Time Explained

When you pour cement, the clock starts immediately, but “drying” is misleading terminology. What’s actually happening is a chemical reaction called hydration. Within 24-48 hours, your cement reaches what’s called “initial set,” meaning it’s hard enough to walk on without leaving footprints. But here’s the catch—it’s nowhere near fully cured.

Think of initial set like a cake that’s cooled enough to touch but still soft inside. You can remove the forms and walk carefully on the surface, but heavy loads will damage it. This is the window where many DIYers make their first mistake: assuming the job is done.

Full Cure Timeline Breakdown

Standard Portland cement follows a predictable schedule, though “predictable” depends on conditions. Here’s the real timeline:

- 24 hours: Can support light foot traffic

- 3-7 days: Reaches about 50-75% strength; safe for light vehicle traffic

- 14 days: Approximately 90% cured; can handle normal use

- 28 days: Full cure achieved; 100% design strength

That 28-day mark is industry standard for a reason. Professional contractors plan projects around this timeline, and specifications for commercial work mandate waiting the full period before heavy use. Residential work often follows the same rules, even if homeowners get impatient.

Factors Affecting Drying Speed

Cement doesn’t dry like paint—it cures through a chemical process that requires moisture, not escape from it. This is where most people get confused. You can’t speed up cement by drying it out faster. In fact, you want to keep it moist during the curing process.

The variables that actually matter are concrete mix design, water content, additives, and environmental conditions. A contractor can use quick-set cement to reduce timeline, but standard mixes follow the schedule above regardless of how much you want them to hurry.

Temperature and Humidity Impact

Temperature is the biggest variable. Cement cures through a chemical reaction that slows dramatically in cold weather. Here’s what happens:

- Above 70°F: Normal curing timeline applies

- 50-70°F: Curing slows; add 50% more time

- Below 50°F: Curing nearly stops; can take months for full strength

- Below 32°F: Freezing damage risk; don’t pour cement

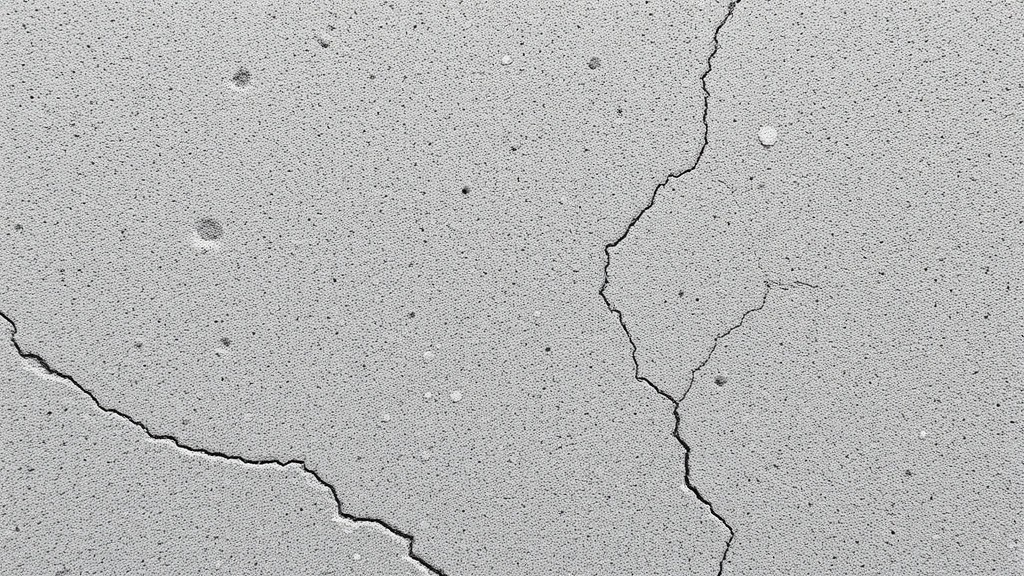

Humidity also plays a role. Dry conditions cause surface cracks because the top dries faster than the interior. Ideally, you want moderate humidity (40-60%) and temperatures between 60-80°F. If you’re pouring in hot, dry weather, you’ll need to mist the surface and cover it with plastic to slow surface drying.

Cement Type Matters Most

Not all cement is created equal. The type you choose directly impacts drying time:

- Type I (Standard Portland): The baseline; follows the 28-day schedule

- Type III (High Early Strength): Reaches usable strength in 3-7 days; full cure in 14 days

- Type V (Sulfate Resistant): Slower curing; useful in specific soil conditions

Quick-set or fast-track mixes use additives and different ratios to accelerate the process. These can be ready for light use in 48 hours, but they cost more and require precise mixing. For most DIY projects, standard Type I cement is the practical choice, even if it means waiting the full month.

Thickness and Depth Considerations

A thin concrete pad cures faster than a thick slab because the chemical reaction happens throughout the entire depth. A 4-inch driveway follows the standard timeline. A 12-inch foundation footing might take significantly longer because moisture has to travel deeper.

This is why large commercial pours sometimes use heat lamps or steam to accelerate curing from the inside. For residential work, you’re dealing with standard thicknesses, so the 28-day timeline holds. Just remember: the surface might feel hard in days, but the interior is still curing.

Common Mistakes to Avoid

I’ve seen these errors ruin otherwise solid work:

- Walking on it too early: Footprints at 2-3 days mean you damaged the surface. Those marks won’t go away.

- Letting it dry too fast: Covering with plastic is good; leaving it exposed in sun and heat causes cracking.

- Removing forms prematurely: Forms support weight while curing. Remove them too early, and the slab sags.

- Applying sealant too soon: Wait at least 28 days, preferably 90 days, before sealing. Trapping moisture inside causes problems.

- Ignoring temperature: Pouring cement in freezing weather is asking for failure. Wait for warmer conditions.

Testing if Cement Is Ready

Don’t guess. Use these methods to check progress:

- Scratch test: Try to scratch the surface with a coin. If it leaves a mark easily, it’s not ready. If it barely scratches, you’re close.

- Weight test: Place a 2×4 board on the surface and stand on it. No indentation means it’s probably safe for foot traffic.

- Moisture meter: Professional-grade meters measure internal moisture. This is the most reliable method for determining true cure.

- Calendar method: The safest approach—just wait the full 28 days. It’s boring but foolproof.

Speeding Up the Process Safely

If you absolutely must accelerate curing, here are legitimate methods:

- Use Type III cement: High early strength formulas reach 50% cure in 3 days. Cost is higher but timeline is real.

- Add accelerators: Chemical additives like calcium chloride speed hydration. Follow manufacturer instructions precisely.

- Control temperature: Keep the surface between 60-80°F. In cold weather, use blankets or heat lamps to maintain ideal conditions.

- Maintain moisture: Mist the surface twice daily and cover with plastic. This keeps the chemical reaction active.

What doesn’t work: blowing fans, removing covers to “dry it out,” or applying heat lamps without moisture. These cause surface cracking and actually weaken the concrete.

Frequently Asked Questions

Can you walk on cement after 24 hours?

Light foot traffic is usually safe after 24 hours, but you risk leaving marks or causing damage. Wait 3-7 days for normal walking without concern, and 14 days before putting furniture or heavy items on the surface.

How long before driving on concrete?

Most contractors recommend waiting 7 days minimum before light vehicle traffic, though the surface may feel hard at 3-5 days. For heavy vehicles or frequent traffic, wait the full 28 days. Parking a car on concrete at day 5 might create permanent depressions.

Does concrete continue to harden after 28 days?

Yes, but very slowly. Concrete reaches about 99% of its design strength at 28 days. It continues to gain strength for years, but the practical difference is negligible after the first month. The real benefit of waiting beyond 28 days is ensuring internal moisture has fully dissipated before sealing.

What if it rains on fresh concrete?

Rain during the first 24-48 hours can damage the surface, creating a rough texture or washing away cement. If rain is forecast, cover the pour with plastic sheeting. After 48 hours, light rain is usually fine. Heavy rain might cause surface washout up to 7 days, so keep covers handy.

Can you seal concrete before 28 days?

No. Sealing too early traps moisture inside, causing spalling and damage. Wait at least 28 days, ideally 60-90 days, before applying any sealer. The concrete needs to fully cure and dry internally before you seal the surface.

Why does concrete feel hard but still be wet inside?

The surface hardens through hydration while the interior is still actively curing. Imagine a chocolate shell around a liquid center—the outside is set, but moisture is still traveling through the concrete. This is why you see “blush” or white powder on sealed concrete sealed too early; trapped moisture trying to escape.

The Bottom Line

How long does cement take to dry? The honest answer: 28 days for full cure, though you can use it much sooner with caution. The surface feels hard in days, but the real strength develops over weeks. Temperature, humidity, cement type, and thickness all affect the timeline, so there’s no one-size-fits-all answer.

The key is patience. Yes, you could probably walk on that driveway at day 5. But if you wait 14 days, you eliminate risk entirely. And if you wait 28 days before sealing or applying heavy loads, you’re guaranteed professional results. Those 4 weeks of waiting beat months of dealing with cracks and damage.

For more detailed guidance on concrete projects, check out resources from Family Handyman, which covers concrete basics thoroughly. The This Old House team also provides excellent step-by-step concrete work guides. And for technical specifications, Bob Vila’s concrete articles offer detailed breakdowns of different cement types and applications.

If you’re working on other home projects while waiting for concrete to cure, you might tackle preventive maintenance elsewhere. Learn how to clean a washing machine to keep your appliances in top shape, or find out how to unclog a toilet fast if plumbing issues pop up during your project timeline.