Metal roofing is one of the best decisions you can make for your home—if you do it right. A properly installed metal roof can last 40-70 years, withstand 140 mph winds, and cut your cooling costs by up to 25%. But here’s the real talk: how to install metal roofing is a project that demands respect. One mistake—a misaligned panel, a fastener in the wrong spot, or improper flashing—and you’re looking at leaks, rust, and a roof that fails way before its time.

I’ve seen homeowners and contractors alike rush through metal roofing installation, thinking it’s simpler than asphalt shingles because the panels are bigger. Wrong. Metal roofing requires precision, the right tools, and a solid understanding of how water moves across your roof. The good news? If you’re experienced with roofing or willing to learn methodically, how to install metal roofing is absolutely doable as a DIY project—or you’ll at least understand what a pro should be doing.

This guide walks you through every step of how to install metal roofing safely, from prep work to the final fastener. We’ll cover materials, tools, common pitfalls, and the safety practices that keep you alive on that roof.

Safety First: Gear and Precautions

Before you even think about touching a metal panel, let’s talk about not dying. Roof work kills people. According to OSHA data on roofing fatalities, falls are the leading cause of death in roofing. Metal roofing adds another layer of hazard: the material is slick, especially when wet or covered in morning dew.

Safety Warning: Never work on a wet roof. Metal is as slippery as ice when damp. Wait for dry conditions, and if rain rolls in, stop immediately. A few hours lost to weather beats a trip to the ER.

Essential Safety Gear:

- Fall Protection: A full-body harness rated for roofing, tied off to a secure anchor point (ridge beam, roof bracket, or cable system). This is non-negotiable if your roof pitch is steeper than 4:12.

- Footwear: Soft-soled shoes with good grip. Hard-soled work boots can actually make you slip on metal—counterintuitive but true.

- Gloves: Cut-resistant gloves. Metal panels have sharp edges that will slice your hands open faster than you’d think.

- Eye Protection: Safety glasses. Metal shavings and fastener debris fly everywhere during installation.

- Hearing Protection: If you’re using power tools, wear earplugs or earmuffs. Metal roofing installation is loud.

- Hard Hat: Wear one if you’re working near eaves or have spotters below. Dropped tools are a real hazard.

- Ladder Stability: Use a ladder stabilizer or standoff to keep your ladder away from the roof edge. A ladder sliding sideways while you’re climbing is a nightmare.

Check the weather forecast obsessively. Overcast days are fine—rain is not. Wind over 15 mph makes roofing miserable and dangerous; wait it out. Early morning or late afternoon is ideal because the metal hasn’t expanded from heat yet, and you’ll have better grip.

Preparing Your Roof for Metal Installation

This is where most DIY projects go sideways. Preparation is 60% of the battle. You can’t just slap metal panels over old shingles and expect success.

Step 1: Remove the Old Roofing

Strip the roof down to the decking. If you’re installing over an existing asphalt roof, you’ll create a moisture trap and void warranties. Rent a dumpster—roofing debris is heavy and bulky. Use a flat shovel or roofing fork to peel up shingles, then pull nails with a pry bar. This is tedious, back-breaking work, but it’s essential.

If you’re removing multiple layers, you might hit nails that have been there 30 years. Wear gloves and take your time. One nail through your foot will ruin your week.

Step 2: Inspect and Repair the Decking

Once the old roofing is gone, inspect every inch of the roof deck. Look for soft spots, rot, or water damage. Press a screwdriver into suspicious areas—if it sinks in easily, that wood is compromised. Mark it and replace that section with new plywood or OSB. Metal roofing is only as good as what’s underneath it.

Check for proper ventilation. Your attic needs airflow. If there’s no soffit ventilation, install it now. Poor ventilation leads to condensation under the metal panels, which causes rust and rot.

Step 3: Install Underlayment

This is your insurance policy. Use a quality synthetic underlayment (not felt—felt absorbs moisture and can trap water). Synthetic underlayment is breathable, won’t rot, and provides a second line of defense against leaks. Roll it out horizontally, starting at the eaves, overlapping each course by at least 6 inches. Staple it every 12-16 inches along the overlap.

At the eaves, let the underlayment hang over the edge by about 1 inch. This directs water into the gutter, not behind it.

Step 4: Install Drip Edge

Metal drip edge goes over the underlayment at the eaves and gables. This simple L-shaped metal strip is crucial—it prevents water from running under the roof system and into your fascia. Use roofing nails spaced 12 inches apart. At the gable ends, the drip edge goes under the underlayment to shed water outward.

Understanding Metal Roofing Materials and Fasteners

Not all metal roofing is created equal, and fasteners matter more than most people realize.

Panel Types:

- Standing Seam: Panels interlock at the seams with a raised rib. Most durable and sleek-looking. Fasteners are hidden, which is great for aesthetics and weather protection. This is the premium option.

- Metal Shingles: Look like asphalt shingles but are metal. Fasteners are exposed. Slightly cheaper than standing seam but more prone to fastener issues over time.

- Corrugated or R-Panel: Budget-friendly, industrial look. Fasteners are exposed. Works fine for sheds and agricultural buildings; less common for residential homes.

- Metal Tiles: Mimic clay or slate tiles. Premium look, premium price. Requires more careful installation.

For residential metal roofing installation, standing seam is the gold standard. Yes, it costs more upfront, but the hidden fasteners mean fewer leak points and better longevity.

Fasteners Are Everything:

This cannot be overstated: wrong fasteners will destroy your roof. Use only fasteners specifically rated for metal roofing. Regular roofing nails are not acceptable. You need:

- Stainless Steel or Coated Steel Fasteners: Galvanized fasteners will corrode and create rust stains. Invest in stainless or high-quality coated fasteners. The price difference is minimal compared to a roof replacement.

- EPDM Rubber Washers: Every fastener must have a rubber washer. This compresses around the fastener head, creating a water-tight seal. Without washers, you have 100+ potential leak points.

- Correct Length: Fasteners must penetrate the decking by at least 1.25 inches. Too short and they don’t grip; too long and they poke through and create water entry points.

- Correct Spacing: Follow the manufacturer’s specifications exactly. Typical spacing is 12-16 inches on center. Too tight and you’re overloading the panels; too loose and panels can shift.

Buy fasteners from your panel manufacturer or a roofing supplier, not a general hardware store. The few dollars you save will cost you thousands in repairs.

Step-by-Step Installation Process

Now we’re installing. Precision is your mantra.

Step 1: Layout and Snap Chalk Lines

Before the first panel goes down, plan your layout. Measure the width of your roof and figure out how panels will fit. Ideally, you want balanced panels on both sides of the roof (not a narrow sliver on one end). Snap chalk lines to mark where each panel starts. These lines keep everything square and aligned.

For standing seam roofing, snap a line 12 inches from the eave edge to mark the first panel. This leaves room for the eave trim and gutter system.

Step 2: Install Eave Trim

Eave trim goes under the first course of panels and over the drip edge. It’s L-shaped and creates a finished edge while directing water into the gutter. Nail it down with fasteners spaced 12 inches apart. Make sure it’s level—if it’s off, your whole roof will be off.

Step 3: Position the First Panel

This is the most critical step. The first panel sets the tone for everything that follows. Align it with your chalk line, square it up, and use a level to confirm it’s straight. If the first panel is crooked, every panel after it will be crooked.

For standing seam panels, the first panel’s edge should be flush with the gable drip edge. Secure it with one fastener at the top to hold it in place while you check alignment.

Step 4: Fasten the First Panel

Once you’re confident it’s aligned, fasten it according to the manufacturer’s specs. Typical fastening for metal shingles or exposed fastener panels:

- Two fasteners at the top (in the flange)

- One fastener in the center of the panel at the eave

- Fasteners spaced 12-16 inches apart down the length of the panel

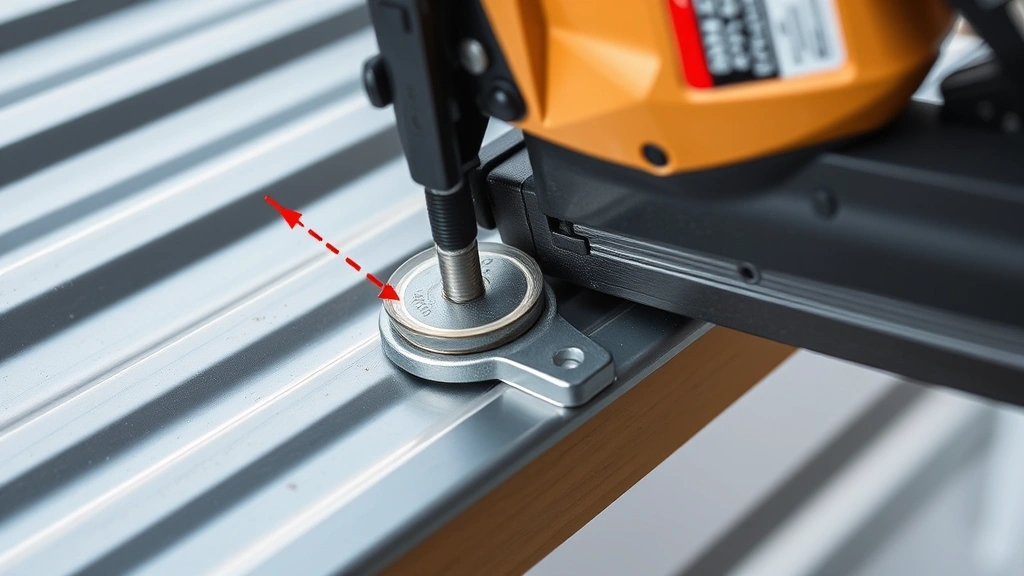

For standing seam panels, fasteners go through the flat rib, hidden from view. Use a pneumatic nailer with a roofing gun (not a framing nailer—different pressure). If you’re hand-nailing, use a hammer and nail punch to avoid denting the metal.

Pro Tip: Drive fasteners straight. A fastener that’s even slightly angled won’t seat properly, and the washer won’t create a tight seal. Take your time. One fastener per 5-10 seconds is a good pace.

Step 5: Install Subsequent Panels

Each panel overlaps the previous one by one rib or interlocking seam. For metal shingles, overlap is typically 1.5 inches. For standing seam, the seams lock together mechanically—no overlap needed on the sides, just on the end laps (typically 6 inches).

As you move across the roof, check alignment every 3-4 panels. If you’ve drifted, correct it gradually rather than trying to fix it all at once. Use a snap-lock punch tool (for standing seam) or sealant (for exposed fastener panels) at overlaps to ensure a watertight connection.

Step 6: Cut and Fit Panels at Roof Edges

The last panel on each side of the roof will need to be cut. Use a metal-cutting circular saw blade or a nibbler tool. Wear eye protection—metal shavings are sharp and fly fast. Cut slowly to avoid denting the panel. After cutting, use a file to smooth the cut edge so it doesn’t snag gloves or hands.

Flashing, Valleys, and Transitions

Flashing is where how to install metal roofing gets technical. This is where most leaks originate if done wrong.

Ridge Cap Installation

The ridge cap is the metal trim that covers the peak of your roof. It’s both functional and decorative. Install it after all panels are in place. Ridge caps overlap the top of the panels by about 2 inches on each side. Fasten with fasteners spaced 12 inches apart, with washers on every fastener. Use sealant (polyurethane or silicone) under the overlap to prevent wind-driven rain from getting underneath.

Valley Flashing

If your roof has valleys (where two roof planes meet), you need valley flashing. This is custom metal work that directs water down the valley without allowing it to pool or back up under the panels. Valley flashing is typically installed before panels go down. It’s folded and shaped to fit the valley, then fastened with hidden fasteners. Water should flow freely down the valley without any obstruction.

For metal roofing, standing seam valleys are best because fasteners are hidden. Open valleys (with exposed fasteners) are more prone to leaks.

Chimney and Vent Flashing

Chimneys, vent pipes, and skylights require custom flashing. This is where metal roofing gets complicated. Each penetration needs its own flashing kit designed for metal roofing.

- Vent Pipe Flashing: A rubber boot with a metal collar that slips under the panel above and over the panel below. The rubber compresses around the pipe and creates a seal. Fasten with hidden fasteners in the upper panel.

- Chimney Flashing: Custom L-shaped metal that wraps around the chimney. The upper flashing tucks under panels above; the lower flashing sits on top of panels below. Use roofing sealant at all joints.

- Skylight Flashing: Similar to chimney flashing but with a curb around the opening. Install according to the skylight manufacturer’s instructions.

All flashing should be sealed with polyurethane or silicone sealant. Think of sealant like the caulk in a bathtub—it fills gaps and prevents water from sneaking through. Use a caulk gun and apply a continuous bead along all joints.

Gable End and Rake Trim

The gable ends (sides of the roof) need trim to finish the job. Rake trim or gable trim covers the exposed edge of the panels and ties into the fascia. It’s typically L-shaped and fastened with fasteners spaced 12 inches apart. Install it after the panels are in place, and seal all joints with sealant.

Common Mistakes and How to Avoid Them

I’ve seen these mistakes over and over. Learn from others’ failures.

Mistake #1: Over-Tightening Fasteners

This is the #1 cause of metal roofing leaks. When you over-tighten a fastener, you compress the rubber washer too much, and it loses its seal. The washer should be snug but not crushed. Think of it like tightening a jar lid—firm, not white-knuckle tight. If you’re using a pneumatic nailer, set the pressure correctly. If hand-nailing, use a nail punch to drive the fastener home without denting the metal around it.

Pro Tip: Practice on scrap panels first. Feel the difference between a properly seated fastener and an over-tightened one. Once you develop the touch, you’ll nail it consistently.

Mistake #2: Fastening in the Wrong Spot

Fasteners must go through the flat part of the panel, not the rib (for exposed fastener panels). For standing seam, fasteners go through the rib itself, but in the right location per the manufacturer. If you fasten in the wrong spot, the panel can’t expand and contract, leading to fastener pullout and leaks.

Mistake #3: Skipping Underlayment or Using the Wrong Type

Underlayment is your safety net. Don’t skip it. Don’t use felt—it’s outdated and absorbs moisture. Use synthetic underlayment rated for metal roofing. It’s breathable, won’t rot, and lasts the life of the roof.

Mistake #4: Poor Flashing Installation

Flashing is where water enters. Every seam, every penetration, every edge must be sealed. Don’t cheap out on sealant. Use a quality polyurethane or silicone product rated for metal roofing. Apply it generously. Water will find the tiniest gap if you let it.

Mistake #5: Ignoring Thermal Expansion

Metal expands and contracts with temperature changes. A metal roof can move up to 1/2 inch with seasonal temperature swings. If you fasten panels too tightly or don’t allow for movement, fasteners will pull through and panels will buckle. Fasteners should be snug but allow for panel movement. This is why spacing matters—fasteners too close together don’t allow enough flex.

Mistake #6: Installing on a Wet or Damp Roof

Moisture trapped under metal panels will rust the underside and cause condensation issues. Make sure the roof deck is completely dry before installing panels. If it rains during installation, stop work and let everything dry before continuing. This might cost you a day, but it prevents months of problems.

Post-Installation Inspection and Maintenance

Installation doesn’t end when the last fastener is driven. Inspection and maintenance are ongoing.

Post-Installation Inspection

Before you call the job done, inspect every fastener, every seam, and every flashing. Walk the roof (safely, with fall protection) and check:

- All fasteners are seated properly with no exposed threads

- No fasteners are missing or loose

- Sealant is applied at all seams and flashing

- Panels are aligned and not buckling

- Ridge cap and trim are secure

- Gutters are clear and functioning

Take photos for your records. If issues arise later, you’ll have documentation of the installation condition.

Annual Maintenance

Metal roofing is low-maintenance compared to asphalt, but it still needs attention. Once a year (ideally in spring):

- Inspect for loose fasteners and tighten if needed (gently—don’t over-tighten)

- Check sealant at flashing and seams; re-seal if cracked or missing

- Clear debris from valleys and gutters

- Look for rust or corrosion, especially at fasteners

- Inspect trim and rake edges for separation or gaps

Metal roofing can last 40-70 years with proper maintenance. Asphalt shingles need replacement every 15-20 years. The upfront cost of metal roofing pays for itself in longevity and durability. Family Handyman’s metal roofing guide offers additional maintenance tips worth reviewing.

For detailed installation specs and manufacturer recommendations, consult This Old House’s roofing section or your panel manufacturer’s technical documentation. Every product is slightly different, and following the manufacturer’s instructions is critical.

Frequently Asked Questions

Can I install metal roofing over existing asphalt shingles?

– No. You must remove the old roofing first. Installing over asphalt shingles creates a moisture trap, voids warranties, and leads to premature failure. The extra weight is also a concern. Strip it down to the deck, inspect for damage, and start fresh. It’s extra work upfront but essential for longevity.

What’s the difference between standing seam and exposed fastener metal roofing?

– Standing seam has hidden fasteners in the seams, making it more aesthetically pleasing and less prone to fastener-related leaks. Exposed fastener panels (metal shingles or corrugated) have fasteners you can see, which are easier to install but more vulnerable to weather and fastener failure over time. Standing seam is the premium option for residential homes.

Do I need a permit to install metal roofing?

– Yes, in most jurisdictions. Roofing work requires permits and inspections. Check with your local building department. Permits ensure the work meets code and can affect insurance and home resale value. DIY installation without permits can create liability issues if something goes wrong.

How much does metal roofing cost?

– Material costs range from $7-15 per square foot for exposed fastener panels to $12-25+ for standing seam. A typical 2,000 sq ft roof costs $1,400-5,000+ in materials. Labor adds another $1,500-5,000+ if you hire a contractor. DIY saves labor costs but requires significant time and skill. Metal roofing costs more upfront but lasts 2-3x longer than asphalt, making it cost-effective over time.

Is metal roofing noisy in the rain?

– This is a common myth. With proper underlayment and insulation, metal roofing is no noisier than asphalt. The underlayment absorbs sound, and attic insulation dampens any noise. In fact, many people find the sound of rain on a metal roof pleasant and soothing.

Can metal roofing be installed on a low-slope roof?

– Yes, but with caution. Metal roofing works best on roofs with at least a 3:12 pitch (3 inches of rise per 12 inches of run). On lower slopes, water drainage is slower, increasing the risk of pooling and leaks. If you have a low-slope roof, use standing seam with proper flashing and ensure excellent drainage. Consult the manufacturer’s minimum pitch requirements.

What should I do if fasteners start to rust?

– Rust on fasteners indicates corrosion. This happens when you use the wrong fastener material (galvanized instead of stainless or coated). If you notice rust, address it immediately. Remove the affected fastener, replace it with a stainless or properly coated fastener, and inspect the washer. If rust is widespread, you may need professional help to assess the extent of the problem.

How do I prevent condensation under metal roofing?

– Condensation happens when warm, moist air from the attic meets the cold underside of the metal roof. Prevent it by ensuring proper attic ventilation (soffit and ridge vents), using breathable underlayment, and maintaining adequate insulation. If condensation is already an issue, install attic fans or improve ventilation. Never seal your attic completely—it needs airflow.

Can I walk on metal roofing after installation?

– Yes, but carefully. Metal roofing is durable and can support foot traffic, but it’s slippery, especially when wet. Use soft-soled shoes, avoid walking on high ridges, and be cautious near edges. If you need to access the roof for maintenance, use a ladder and fall protection. Avoid unnecessary traffic on the roof—the less you walk on it, the longer it lasts.

What’s the warranty on metal roofing?

– Warranties vary by manufacturer and product. Standing seam typically comes with 20-50 year warranties covering material defects. Exposed fastener panels often have 10-20 year warranties. Labor and installation defects are usually not covered. Always review the warranty terms and keep documentation of your installation. Proper installation is key to honoring the warranty.

Metal roofing is a significant investment, but when installed correctly, it’s one of the best decisions you can make for your home. Take your time, follow the manufacturer’s specs, and don’t skip steps. The roof over your head is too important to rush. If you’re not confident in your abilities, hire a professional. A quality installation is worth the cost. For additional guidance, Bob Vila’s roofing expertise provides practical insights, and Family Handyman’s general roofing guide covers foundational concepts applicable to all roof types.